Reasons to stop manually wrapping your products

Inconsistent wrap quality – uneven tension can make pallets unstable.

Slow and labor-intensive – reduces throughput and increases labor costs.

Physical strain – repetitive motion can cause injuries.

More material waste – humans often use excess film.

Safety risks – moving around heavy pallets increases accident potential.

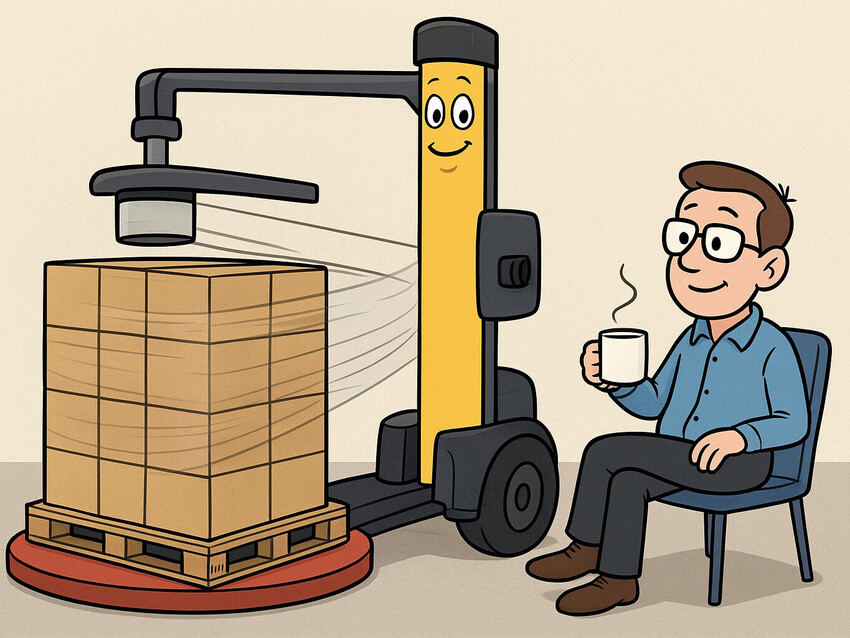

Reasons you need a pallet wrapper

Consistent wrap quality – ensures stable, secure pallets every time.

Faster throughput – wraps pallets quickly, boosting efficiency.

Labor savings – reduces manpower and associated costs.

Reduced material waste – precise film tension minimizes excess use.

Improved safety – less physical strain and lower accident risk.

Scalable for high volume – handles large numbers of pallets reliably.